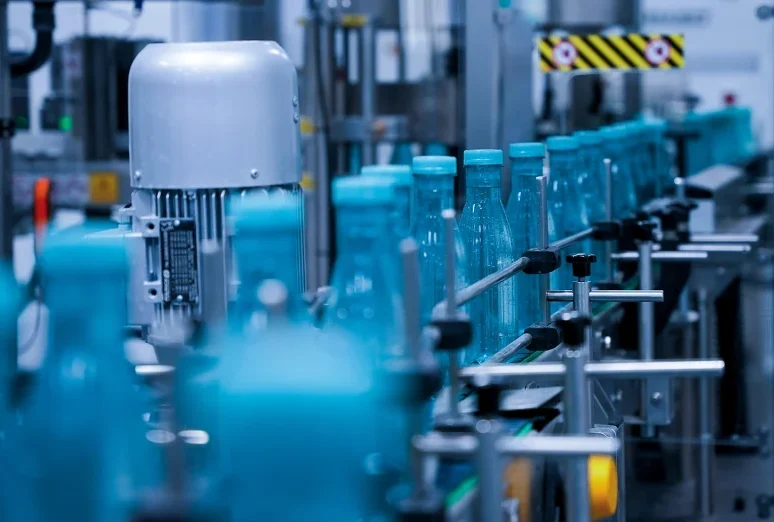

PET bottle filling machines are among the most popular and widely used types of equipment in the product packaging industry. As you know, the packaging section is one of the main concerns for any production facility. In the past, this process was carried out manually by human labor. However, with the advent and advancement of various filling machines, the task of filling has gradually become easier and faster. Today, we see a wide range of liquid filling machines designed for products with different viscosities and physical properties.

These machines are available as fully automatic or semi-automatic liquid filling machines, allowing each facility to choose the option that best fits its production line, initial budget, and other requirements. Additionally, the number of nozzles on a PET bottle filling machine also affects its price.

PET Bottle Filling Machine

Before we discuss what a PET bottle filling machine is, let’s first explain PET itself. PET (Polyethylene Terephthalate) is a type of plastic material, one of its uses being in the production of beverage bottles. These bottles are typically used for water and, like other plastic types or those containing organic and petroleum-based compounds, they are not hazardous.

The material used in PET bottles is free of polyethylene, which gives them unique physical and chemical properties. These bottles are highly resistant to abrasion, and their flexibility is greater compared to other plastic types. They also exhibit good strength against impact. PET bottles are leak-proof, ensuring that liquids packaged in them are not wasted. Additionally, these bottles are recyclable, making them environmentally friendly and leading to their use over plastic alternatives.

However, the PET bottle filling machine is a type of filling machine specifically designed for this type of container. It’s important to note that this machine is not only used for filling water or beverage bottles; it can also be used for filling various jugs and bottles containing herbal extracts, essential oils, and other different chemicals.

A bottle filling machine consists of the following components:

- Sorting system

- Filling system

- Collection system

- Conveyor system

- Distribution system

- Detection system

- Filling system

Next, we will examine the types of bottle filling machines based on their operating mechanism and the number of nozzles.

Types of PET bottle filling machines

As mentioned, filling machines are generally categorized from various aspects. These aspects include the type of product, product viscosity, filling mechanism, number of nozzles, and similar factors. Based on this, there are three different types of filling machines for PET bottles.

✅ One nozzle, two nozzles, up to six nozzles

One of the classifications of filling machines, especially PET bottle fillers, is based on the number of nozzles. The higher the number of nozzles, the higher the production rate per minute, and consequently, the greater the final volume of work. However, the price of the machine increases accordingly. Generally, each nozzle is capable of connecting to one container, which results in an increase in the final product as the number of nozzles increases.

✅ Automatic PET bottle filling machine

Another type of filling machine is the automatic version. Automatic machines do not require human intervention, and the entire process from placing the container to the final stage, which includes packaging and labeling, is carried out by the machine itself. The packaging speed of products with automatic machines is very high, producing around two to four thousand units per hour. However, automatic machines are more expensive compared to semi-automatic or even manual models, and this higher price is due to their special and advanced functionality. If the automatic filling machine has more nozzles, it will directly impact its price.

✅ Semi-automatic PET bottle filling machine

Another type of PET bottle filling machine is the semi-automatic model. In this model, part of the work is done automatically by the machine, while the other part is performed by the operator and human labor. Therefore, the presence of an operator is required during the operation of this machine. Semi-automatic machines are less expensive than fully automatic models, but their production rate per hour is lower. These machines are an ideal choice for small businesses or production lines with low daily order volumes.

Buying a cheap PET bottle filling machine

After reviewing PET bottle filling machines and their types, we come to the purchase stage. Undoubtedly, every company seeks to buy the best product and machine at a lower price. If you plan to buy PET bottle filling machines in bulk, you can obtain them at a lower price. When purchasing these machines, it is very important to pay attention to the store, the manufacturer’s brand, the features and specifications of the machine, the material of the body, and other factors.

The more advanced the machine and the higher the number of nozzles, the higher its price will be. In contrast, semi-automatic or manual machines with fewer nozzles have a lower price. Each individual or company can choose and purchase different types of PET bottle filling machines based on their daily production volume and needs.

Identifying a genuine PET bottle filling machine

When purchasing a bottle filling machine, it is crucial to distinguish between genuine and counterfeit devices. Since this machine is directly linked to the final product and its packaging, it significantly impacts the product’s quality. If fake or low-quality machines are used for packaging, your product will lose its authenticity and quality, and you will also experience considerable material wastage. Therefore, we recommend purchasing your filling machine from reputable companies.

Since the price of this machine is high, purchasing without proper research or making an unsuccessful purchase can result in significant losses for companies.

Summary

PET filling machines are among the most widely used types of machines in the production lines of various industries. These machines are categorized based on their operating mechanism, the type of liquid, and the container type. For this reason, today we see various types of PET bottle filling machines. The machines used for these bottles are available in automatic and semi-automatic models, with a range of one to six nozzles.

Frequently Asked Questions

✅ What is a PET bottle?

PET is one of the materials used for packaging, manufacturing, and producing bottles, jugs, and more. It is used to store various beverages such as water, fruit juices, and even chemicals.

✅ What is a PET bottle filling machine?

This machine is one of the most commonly used industrial machines for filling desired liquids into PET bottles.

✅ What are the types of PET bottle filling machines?

Filling machines are categorized from various aspects, and for PET bottle filling, we have different categories, including single nozzle, two nozzles up to six nozzles, automatic filling machines, and semi-automatic filling machines.

✅ What factors are important to consider when purchasing a PET bottle filling machine?

When purchasing this product, it is important to pay attention to its authenticity, as well as other factors such as the material of the body, the manufacturer’s brand, the year of production, and more.