One of the most important and critical sections in various industries such as cosmetics, food, paint, etc., is the filling section. Fillers come in different types, and they are selected based on the product type and the type of tube. In this content, we will specifically discuss the tube filling machine for cosmetic and personal care products.

These products must be packaged in the final container under completely hygienic conditions, free from any contamination, and without direct human intervention. Therefore, using these machines is essential for maintaining hygiene standards. Additionally, using fillers for packaging personal care products helps prevent product wastage.

Cosmetic and personal care tube filling machine

Cosmetic and personal care products are usually filled into plastic or sometimes metal tubes, so the type of filling machine varies accordingly. Additionally, attention must be given to the tube material, as well as the product’s viscosity, density, and type.

When purchasing a cosmetic and personal care tube filling machine, factors such as initial budget, type of product, production line, customer order requirements, and similar considerations must be taken into account. The machine can be chosen as manual, semi-automatic, or fully automatic. Undoubtedly, for industrial operations and large-scale production, a fully automatic tube filling machine is the best choice.

As we mentioned, the type and material of the tube are also highly important when selecting the machine. Therefore, it is advisable to first study the various types of tubes used in the cosmetic and hygiene industry and then choose the appropriate filling machine based on the product type and tube material.

Selection of tube type and material

To purchase a tube filling machine for cosmetic and hygiene products, the first step is to select the desired tube type. One of the primary factors in tube selection is ensuring no interaction between the filled substance and the tube’s inner wall. Typically, the most commonly used tubes in these industries are plastic. Plastic tubes are widely used for filling toothpaste, various creams, foundation, other hygiene products such as cleansers, skincare creams, and similar items.

However, cosmetic and hygiene products are also filled in metal, aluminum, and laminated tubes. These types of tubes are commonly used for packaging medicinal ointments such as betamethasone ointment, burn ointments, zinc ointment, and various other products.

After understanding the different types of tubes based on their material, you can choose the appropriate filling machine accordingly. However, the tube alone is not the only determining factor; the viscosity and composition of the product also play a crucial role in selecting the right filling machine.

What are the types of tube filling machines for cosmetic and hygiene products?

In general, filling machines are categorized based on their operating mechanism or the type of product. Based on the operating mechanism, there are three types of filling machines: manual, semi-automatic, and fully automatic.

✅ Fully Automatic Tube Filling Machine

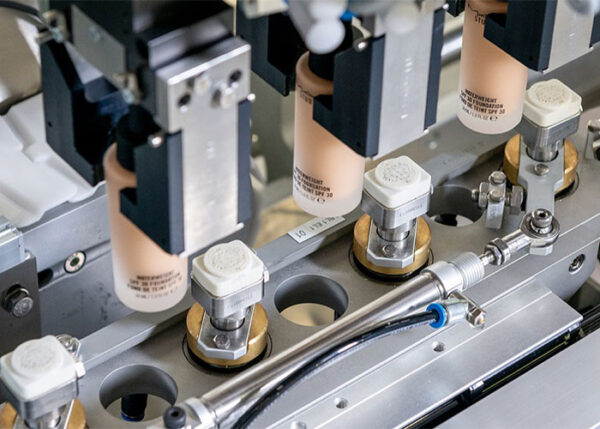

The most commonly used model of filling machines is the fully automatic version, which is particularly used in large factories and various industries. This machine requires no human intervention or operator presence, and the entire filling and packaging process is carried out at a very high speed without the need for a person to be present.

These machines are highly suitable for factories with large orders and extensive production lines. Some of the advantages of using this type of fully automatic tube filling machine for cosmetic and hygiene products include high packaging capacity per hour, compatibility with aluminum, plastic, and laminated tubes, an automatic tube feeding system, an automatic labeling system, an automatic cleaning system, and more.

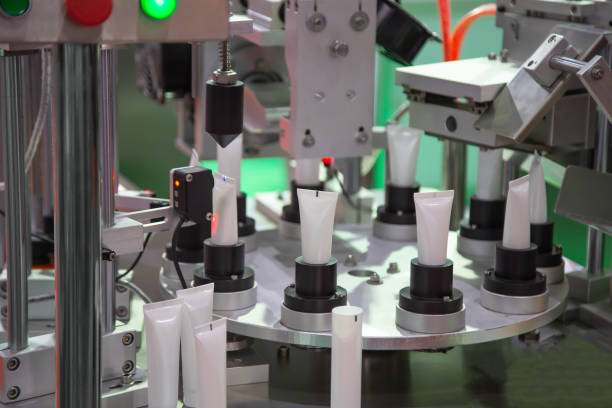

✅ Semi-Automatic Tube Filling Machine

The semi-automatic tube filling machine is another type of filler that, in terms of performance, is slightly less efficient than the fully automatic model but comes at a more affordable price. This machine is typically suitable for small, newly established factories, allowing them to avoid high initial equipment costs. In these machines, half of the process is automated, while the other half requires human intervention, with an operator guiding the tube toward the designated filling nozzle.

The packaging capacity of this machine is lower compared to the fully automatic model, but it can still fill between 1,000 to 1,500 tubes per hour. This type can be used for plastic, laminated, and aluminum tubes in the cosmetic and hygiene industries.

✅ Manual Tube Filling Machine

The manual tube filling machine has a much simpler operation and, accordingly, a significantly lower price. This machine is suitable for small, newly established factories and is typically used for packaging specific products, including detergents and cosmetic and personal care items such as lotions, ointments, and similar products.

These machines require constant operator presence and some of their features include compatibility with laminated and plastic tubes, an affordable price, the ability to package 400 to 600 tubes per hour, lower speed for filling tubes with sensitive and chemical products, and similar characteristics.

Purchase of cosmetic and hygiene product tube filling machines from Radan Machine

After reviewing the different types of tubes and tube filling machines for cosmetic and hygiene products, you are undoubtedly well-equipped to make the right choice for this machine. To view the price of the cosmetic and hygiene product tube filling machine, simply visit the tube filling page for cosmetic and hygiene products on the Radan Machine website, where you can choose your desired machine from the available options and view its price.

After making your final decision, you can add the product to your cart and make a secure and safe purchase by paying for it. Radan Machine strives to provide the best and highest quality tube filling machines, including manual, semi-automatic, and fully automatic types, to valued buyers and factory owners.

Summary

Filling products into specialized containers is a major concern for industries, which is now addressed by various filling machines. Depending on the viscosity of cosmetic and hygiene products, automatic or semi-automatic fillers can be used, including pump, gravity, or piston-cylinder types.

Frequently Asked Questions

✅ What are tube filling machines for cosmetic and hygiene products used for?

These machines are used for filling various cosmetic creams, ointments, facial cleansers, and more.

✅ What is the basis for selecting cosmetic and hygiene product filling machines?

The selection of this machine is influenced by factors such as the type and viscosity of the product, production rate per hour, budget for purchase, and more.

✅ Which type of filling machines are used for cosmetic and hygiene products?

In general, filling machines are divided into three categories based on their mechanism: manual, automatic, and fully automatic. For filling cosmetic and hygiene products, automatic or semi-automatic models with cylinder, piston, and pump types are more suitable.