Today, due to the high importance of packaging, various machines and equipment are used in production lines in factories, one of which is the liquid filling machine. This machine makes the packaging process of liquid products (with various viscosities) such as beverages, detergents, and oils possible. Of course, liquid filling machines are designed and produced in different types, and in this article from Radan Machine, we will focus on two of them: the tri-block and monoblock filling machines. Please stay with us until the end.

What is a tri-block filling machine?

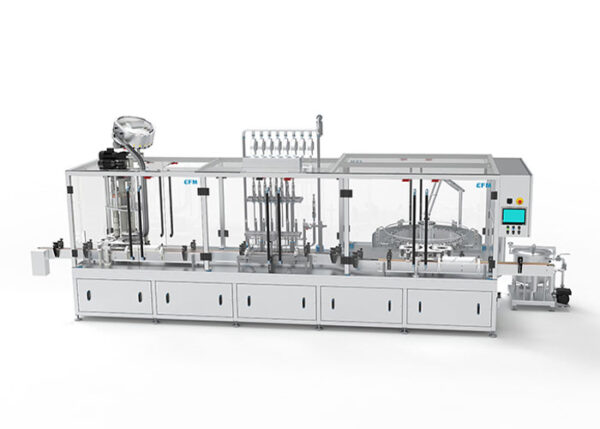

The tri-block filling machine, as you might guess from its name, is a combination of three machines that perform different tasks. This machine includes mechanisms for washing, filling, and capping (for plastic caps), all integrated into a single unit. The tri-block filling machine can be used for packaging various edible liquids, including mineral water, fruit juice, soda, doogh, herbal drinks, oil, and more, in plastic bottles ranging from 250 to 2000 milliliters.

The tri-block filling machine uses a gravity system for filling and packaging liquids. This machine is fully automatic and is equipped with features such as a touch screen for electronic control (PLC) and electronic speed control (frequency inverter). Additionally, depending on the production volume of the factory, the machine can have a specific number of nozzles. The number of nozzles typically ranges from 4 to 32.

The tri-block filling machine operates in three stages: The first stage is the washing of containers, during which the bottles used for packaging the products are thoroughly cleaned to be free of any contamination. Then, the conveyor belt transfers the bottles to the nozzles. The desired liquid is filled into the bottles through the nozzles, and in the third stage, the conveyor belt moves the filled bottles to the capping section of the machine. The bottles are completely capped in this stage, and once the process is completed, they are transferred to the next stage in the packaging line.

Applications and advantages of the tri-block filling machine:

Now, let’s take a closer look at the tri-block and monoblock filling machines. The tri-block machine is used in liquid production lines and is employed in all industries that require washing, liquid filling, and capping mechanisms. As mentioned earlier, this machine is primarily used for filling edible liquids, but it is not limited to that. For example, liquids such as engine oil or brake fluid can also be filled with the tri-block machine. In industries like chemicals, automotive, and detergents, manufacturers require a machine that can fully package their products while adhering to hygiene standards. Therefore, various liquids, including dishwashing liquid, hand soap, brake fluid, antifreeze, and more, are filled using the tri-block machine.

The main advantage of the tri-block machine is its high speed and the ability to perform three tasks simultaneously. By carrying out the three stages of washing, filling, and capping, this machine significantly increases the overall speed and quality of the work. Its automatic nature is another advantage, eliminating the need for manual labor, making it highly suitable for high-capacity production lines.

What is a monoblock filling machine?

The Monoblock filling machine is another type of liquid filling machine that differs slightly from the Triblock machine. Before we discuss the differences between the Triblock and Monoblock filling machines, it’s important to become familiar with the Monoblock as well. The operation of the Monoblock is similar to the Triblock, with the main difference being that the Monoblock does not include a bottle washing mechanism and only performs the filling and capping functions.

Monoblock filling machines are built in various designs, including linear and rotary, and typically have 4 to 18 nozzles. These machines are mostly used in small workshops or for filling materials like radiator water, where bottle washing is not required.

Types of tri-block and monoblock filling machines

Now that we are familiar with the operation, advantages, and applications of the tri-block and monoblock filling machines, let’s explore the different types of these machines. Various types of monoblock filling machines include piston-cylinder liquid fillers, pump-based fillers (for both thin and thick liquids), and gravity fillers. Let’s take a closer look at these machines:

Types of monoblock filling machines

- Gravity Capper Filler: This machine is used for thin liquids. If the product has low viscosity, it easily flows down from a reservoir located at the top of the machine using gravitational force. This system uses the gravity of the liquid itself to fill the bottles, which is why it is also called a gravity liquid filler. In addition to its simple functionality, this machine is cost-effective.

- Pump Capper Filler: This machine is used for both thick liquids (with high viscosity) and thin liquids (with low viscosity). It has more applications compared to other types of monoblock machines because it can package a wider range of products. One of the specialized applications of this machine is filling grease, which has high viscosity and stickiness. It is also used for filling foamy, sticky liquids, and more.

- Piston Cylinder Filler Capper: This machine offers the highest speed and precision among the other machines mentioned and is excellent for filling thick liquids (with high viscosity). It is ideal for products like tomato paste, offering both high speed and accuracy, though it comes at a higher price. Due to its precision, the piston cylinder filler is also suitable for filling products into containers with capacities of less than one liter.

Types of tri-block filling machines

The tri-block filling machine is capable of filling both thick and thin liquids, but it is categorized based on the types of containers it can fill. Some of the types of tri-block machines include liquid filling machines for polyethylene containers, PET containers, and glass containers. These machines are typically available in models with 12, 18, 24, 32, and 64 nozzles.

The difference between tri-block and monoblock machines

Now that you are familiar with the applications and mechanisms of the tri-block and monoblock filling machines, you can likely guess the differences between them. One of the differences is that the tri-block machine has three main sections: bottle washing, filling, and capping, and is usually used for packaging edible liquids. On the other hand, the monoblock machine has only two main sections: filling and capping, and does not perform the bottle washing process; therefore, it is more commonly used for non-edible liquids.

Final Words

Given the increasing importance of packaging and its impact on attracting and gaining the trust of customers, it is beneficial for companies to gather more information about packaging machines and their applications. Two machines that are particularly important for companies producing various liquids are the monoblock and tri-block filling machines. The tri-block machine has three mechanisms: washing, filling, and capping, whereas the monoblock machine only performs the filling and capping functions. Depending on your production volume and the needs of your company, you can choose to acquire one of these machines.

Frequently Asked Questions

✅Which machine is used for filling and packaging thin liquids?

Considering the mechanism of filling machines, the gravity filling, overflow, and pump filling machines are more suitable for filling thin liquids.

✅What factors should we consider when choosing the appropriate liquid filling machine?

Before purchasing a liquid filling machine, you should consider factors such as the product’s viscosity, the liquid’s behavior (sticky, foaming, etc.), the type of machine, and the number of nozzles.

✅What types of liquids is the triblock filling machine used for?

The triblock filling machine can be used for packaging various food liquids, including doogh, mineral water, fruit juice, and more.