Homogenizers are a type of mixer that use mechanical forces to blend and dissolve liquids or liquid-solid mixtures. High-power homogenizers are used to break down and disintegrate solid particles as well as liquid droplets. This is a physical process that mixes immiscible liquids into an emulsion.

A homogenizer is essentially a positive displacement pump that is connected to a homogenizing valve. Fluids entering the homogenizer pass through a small gap under high pressure. This causes a rapid increase in speed and a decrease in pressure, leading to disruption and dispersion of particles. In this article, we answer questions such as “What is a homogenizer pump?” and “How does a homogenizer pump work?” and fully explain the working method of the homogenizer pump. So, stay with us until the end of the article.

What is a homogenizer?

A homogenizer is a type of mixing device designed to break down solid and liquid particles into a uniform solution. Homogenizers are available as laboratory, benchtop, and industrial equipment for various research and industrial applications. Common uses of homogenizers include mixing and breaking down different materials such as particles, pigments, chemicals, plants, food, cells, tissues, and more. Homogenizers can also be used as by-products of the homogenization process.

Types of Homogenizer Pumps

Homogenizers come in various types, designed for large-scale and industrial production. However, the most commonly used models are the rotor/stator homogenizers, high-pressure homogenizers, and ultrasonic homogenizers.

Rotor/Stator Homogenizer

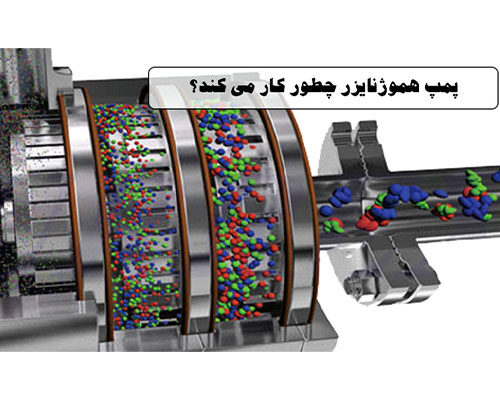

As the name of the rotor/stator homogenizer suggests, the rotor/stator homogenizer consists of a rotor and a stator component. The rotor is a metal shaft that spins at high speed inside the stator. The stator is a metal piece that remains stationary. The rotation of the rotor creates a suction effect that moves the solid-liquid mixture between the stator and rotor, where the solids are reduced to smaller particle sizes.

High-Pressure Homogenizer

The working principle of a high-pressure homogenizer is based on the use of a high-pressure pump and a valve (nozzle, aperture), through which the processed slurry is passed at high flow rates. This reduces the particle size as the particles need to reach a specific small size to pass through the valve. This is particularly important when processing solid materials, as high-pressure homogenizers are prone to clogging.

Ultrasonic Homogenizer

Ultrasonic homogenizer materials must be wet or in a wet phase, meaning that the ultrasonic device is not very efficient in mixing dry powders. However, once the powder is wetted, it becomes the most efficient method for mixing. Ultrasonic homogenizers work well for mixing and dispersing pastes and highly viscous materials. The extremely intense forces generated by the collapse of cavitation bubbles create very powerful shear forces. These physical forces break particles down into much smaller sizes than conventional homogenizers. Therefore, ultrasonic homogenizers are preferred equipment for reliably producing emulsions and dispersions at the nanoscale.

How particles mix in a homogenizer pump

If you’re wondering how a homogenizer pump works, the answer is that homogenization is a mechanical fluid process that pushes the fluid through a small aperture to break apart particles or droplets and reduce their size to create a stable dispersion or emulsion. While all homogenizers typically reduce particle size, high-pressure homogenizers use high pressure to achieve optimal results, with particles usually in the micron or nano range. Homogenizers use various types of forces, which generally provide the most effective particle size reduction results.

Features of Homogenizer Pump

Homogenizers are widely used in the dairy, food and beverage, healthcare and cosmetics, chemical, biotechnology, and pharmaceutical industries. This helps improve product quality and creates a competitive edge. If a homogenizer pump is properly designed, it can enhance products and reduce costs.

Advantages of homogenizing materials

The benefits of using a homogenizer depend on the results it delivers. A homogenizer is used to reduce the particles of a material to the smallest uniform size. Smaller particles mean that a more stable, effective, and consistent product is produced. Nanoparticles have more particles, making it easier to combine them with other materials. As a result, it improves the texture, consistency, and appearance of the final product, leading to enhanced physical, chemical, and biological reactions.

Final word

Considering the above information, we understand that when your goal is to create a uniform mixture of two or more substances that do not easily mix together, there are various options for using mixing methods. One of the most effective options is the homogenizer or homogenization. Homogenization with high pressure breaks the particles and forces the materials into a narrow space to form a uniform substance. This method is used to create a cohesive and consistent mixture. Nowadays, high-pressure homogenization is typically suitable for both micro and nano emulsions. As we promised at the beginning of the article, we provided a complete explanation about what a homogenizer pump is and how it works, so you can acquire them according to your needs. If you have any additional information about the operation of the homogenizer pump that has not been included in the article above, please leave us a comment so we can update the content.

Frequently Asked Questions:

How does the homogenization process work?

The homogenization process involves reducing the size of fat globules into smaller parts that are evenly distributed throughout the milk. Homogenization is typically done by pumping the milk through small nozzles under very high pressure.

What is a Homogenizer Pump?

A homogenizer is essentially a positive displacement pump that is connected to a homogenizing valve. The fluids entering the homogenizer pass through a small gap under high pressure.

How do you homogenize milk?

Homogenization is a process in which milk is sprayed through a specialized device under very high pressure. This breaks down the fat particles and reduces them to a size that allows them to be evenly dispersed throughout the milk.

Does the homogenizer reduce particle size?

High-pressure homogenization is a high-energy fragmentation process that uses high pressure to reduce particle size in a liquid environment.