Every product we purchase has a label, which serves as its identity and provides key information about the product, the manufacturer’s brand, usage instructions, price, ingredients, and more. This is why labels are crucial in the packaging industry. To attach these labels to products, a machine called a label applicator or labeler is used, which is one of the most important machines in production lines. Stay with us in this article as we explore what a label applicator is and what types and applications it has.

What is a label applicator machine?

As we mentioned, a label is a tag attached to the product container that provides us with information about it. Since the label is an important criterion in choosing and purchasing a product, it is crucial to pay close attention to the design and application process. Labels may include product-specific barcodes, which you’ve likely seen on products that you use daily (such as beverages, food items, cosmetics, pharmaceuticals, stationery, etc.).

But what is a label applicator and why is it used in various industries? Since applying labels manually can be a very time-consuming, inconsistent, and exhausting process, label applicator machines are used in production lines. With these machines, products move in a defined sequence, and labels are applied with high speed and precision. Manufacturers, by investing once in purchasing this machine, can save time and reduce labor costs. Label applicators are one of the most essential components of production and packaging lines in industries with medium to high production levels.

Features and advantages of a label applicator machine.

One of the most important advantages of a label applicator machine is its ability to speed up the packaging process and apply labels with great precision. This machine can be used in various industries and environments, including stores, pharmacies, banks, restaurants, and other institutions.

These machines have various ports, making it possible to use them in different locations and allowing them to connect to various devices, including computers, office machines like printers, and more. Other advantages of the label applicator machine include being quiet, space-saving, and performing tasks at a very high speed.

Types of Labeling Machines

Nowadays, label applicator machines are produced in various types, and you should choose the suitable machine based on your needs and budget. It is also recommended to know what types of label applicator machines exist and how they are categorized before making a purchase. To buy different types of label applicator machines, you can visit the relevant link and learn more about the specifications of each one.

Automatic label applicator machine

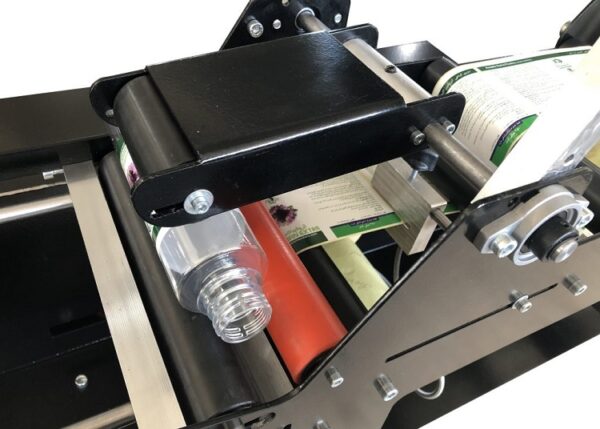

The automatic label applicator machine is one of the most commonly used types of labelers, produced in two types: thermal and pressure-sensitive. The automatic label applicator machine is one of the most important components of production and packaging lines, and its operation works as follows: Products move along a conveyor belt toward the machine, where labels are automatically applied to them.

Semi-automatic label applicator machine

The semi-automatic label applicator machine is also a versatile device used for cylindrical and square containers and products. Equipped with optical fibers, this machine is also used for labeling plastic bottles.

Manual label applicator machine

The manual label applicator is a tool used for labeling products and goods manually. This device is mainly used for applying labels on bottles, and the most important consideration when purchasing it is that the machine should be lightweight and easy to handle to prevent fatigue.

One of the most commonly used label applicator machines is the OPP machine, which is mainly used for bottling mineral water, soft drinks, and other beverages. The advantages of this machine include its high speed (about 10,000 to 30,000 bottles per hour). The design of this machine is rotary, and it has very high speed and precision. You can purchase the OPP label applicator machine through the Radan Machine store.

Applications of the label applicator machine

But what are the applications of a label applicator machine? One of the most important industries where the label applicator is used is the food industry, as the labels on these products provide information about their price, production date, and expiration date. In fact, these labels serve as the product’s identity, which is why they are of great importance. In addition to the food industry, various labels can also be found on goods from other industries.

The label applicator machine can be used for applying labels on various containers, including glass, polyethylene, booklet, PET, cylindrical, and different types of drums in industries such as chemicals, cosmetics, pharmaceuticals, food, and more. In fact, the label applicator is applicable in all industries, and there are no limitations to its use.

Frequently Asked Questions

Which of the label applicator machines is automatic, and which one is semi-automatic or manual?

Machines that do not require human intervention are called automatic machines and perform all tasks with high speed and precision. Semi-automatic machines perform half of the tasks automatically and the other half with the help of an operator, while manual machines are fully operated by the operator.

What is the basis for classifying different types of label applicator machines?

These machines are generally classified into three categories: automatic, semi-automatic, and manual, with each category having subcategories such as pressure-sensitive, dual-purpose, and others.

Are labels also divided into different types?

Labels come in various types, including pressure-sensitive, stretch, wrap-around, cold adhesive, and more, each requiring a suitable machine.

Final Words

In this article, we discussed what a label applicator machine is, the different types it comes in, its advantages, and its applications. In conclusion, we learned that these machines significantly enhance the speed and precision of the production and packaging processes, and their use is highly recommended for all manufacturers. Therefore, if you are among those who need to purchase a label applicator machine, you can explore the various models available on the Radan Machine website and proceed with purchasing the one that suits your needs.