One of the main concerns of industrialists and manufacturers is filling the produced liquid into the desired container. Liquids come in various types, and in this content, we will focus on carbonated liquid filling machines. Carbonated liquid fillers are categorized into two types: those for thin liquids and those for thick liquids, based on the viscosity of the liquid. These fillers generally operate with piston cylinder, pump, or gravity mechanisms, specifically designed for their respective purposes.

Carbonated liquids include beverages such as soft drinks, sparkling water, kefir, dandelion soda, and other similar products. These carbonated drinks or liquids are not very viscous, but to fill them, similar filling machines used for thick liquids are required. This is because high pressure is needed to transfer both the liquid and gas into the final container. Carbonated liquids are typically filled in plastic or metal containers, and the type of filler can be chosen based on whether the container is plastic or metal. In the following content, we will provide more detailed explanations about the different types of carbonated liquid fillers, including their prices, technical specifications, and related considerations.

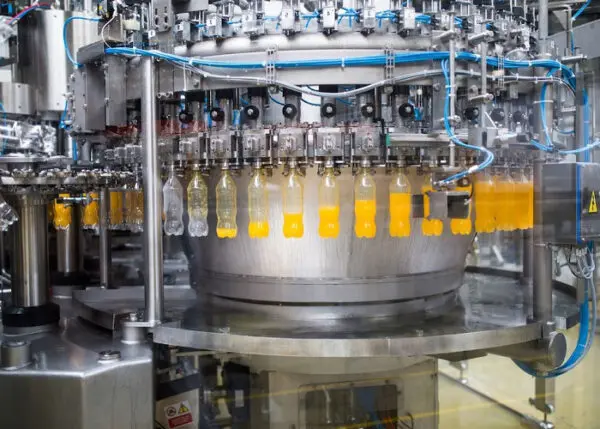

Carbonated liquid filling machine

Carbonated liquids include various types of soft drinks, sparkling water, doogh, malt beverages, and similar products. Different types of liquid filling machines are used to fill these products. One of the key specifications and features of these machines is their filling mechanism. In general, filling machines come in three types: manual, semi-automatic, and fully automatic. For carbonated liquids, semi-automatic or fully automatic models must be used.

The final container can be various types of metal or plastic cans, tubes, etc., depending on the type of liquid, the production brand, and other factors. Typically, for these types of liquids, we see various PET bottles, metal cans, and plastic cans.

Types of carbonated liquid filling machines

Before examining the different types of machines used for carbonated liquids, let’s first look at the various classifications of filling machines. Filling machines are categorized from various perspectives.

Classification based on viscosity

One of these aspects is the viscosity of the liquid, such that specific machines are used for thick and thin liquids. However, carbonated liquids, despite not being very viscous, fall under the category of filling machines for thick liquids.

Classification Based on Mechanism

Another aspect of categorizing filling machines is based on their operating mechanism. Generally, there are three types: manual fillers, semi-automatic liquid filling machines, and fully automatic liquid filling machines. Manual fillers are not suitable for filling carbonated liquids, while semi-automatic or fully automatic fillers can be used depending on various factors such as production requirements, daily output volume, scale of the production line, initial budget, and more.

But the types of fillers that can be used for carbonated liquids include piston cylinder fillers, volumetric fillers, and pump fillers. Each of the mentioned types differs in certain aspects. For example, the accuracy of these fillers varies, and they are also selected based on the amount of liquid to be filled in the container or the type of product being produced.

The production line and filling machine for carbonated beverages in PET bottles.

These filling machines are part of the production line in factories. As mentioned, filling machines can also be classified based on the final container. In factories where the final container is PET bottles, the production line and the method of packaging and filling carbonated liquids are as follows:

- Initially, the filling machine is placed in the designated location. This machine varies based on production capacity, filling speed, motor weight, and more. In general, these machines include the filling section, locking section, cage, main motor, control system, bottle transfer system, sorter, electrical control system, and more. Additionally, some types of PET filling machines have screening and bottle cleaning sections or other components in direct contact with the liquid.

- The operation of the PET bottle filling machine in the production line is as follows: first, empty bottles are quickly transported to the nozzle and filling section with the help of a conveyor belt.

- In the next stage, the nozzle connects to the container’s opening and fills the PET bottle with the carbonated liquid based on the desired weight or volume.

- Following these stages, the containers are cleaned again, and the sealing and labeling, or the application of other information, are carried out. These filling machines, used for carbonated liquids, are equipped with a printer that prints the required information, such as production and expiration dates, onto the PET bottles.

- Finally, the bottles reach the shrink section of the machine, where they are packaged into boxes.

The production line and filling machine for carbonated beverages in cans.

In the previous section, we reviewed the production line of factories where the final container is PET bottles. In this section, we will discuss the production line where the final container is a can. The operation of these machines is similar, but the nozzle design or other components of the filling machine may differ.

- To fill cans with carbonated liquids, the cans are placed on a conveyor belt and moved towards the nozzle.

- Depending on the type of machine, there can be 1 to 6 nozzles on it. Once the nozzle is securely attached to the opening of the can, the carbonated liquid is transferred into the container.

- In the next step, the lid of the container is completely sealed, and it moves on to the labeling section.

- Finally, the prepared cans are packed in bundles of 6 or 12 in the shrinking section, and the final product exits the machine.

Depending on whether the carbonated liquid filling machine is automatic or semi-automatic, the above steps are either fully carried out by the machine or partially done by the machine, with the rest requiring the presence of an operator.

The price of carbonated liquid filling machines.

The price of carbonated liquid filling machines depends on many factors.

- One of these factors is the brand and manufacturer. The more reputable and well-known the brand, the higher the price of its products will be.

- Another factor influencing the price of this device is the materials used in its construction. For example, a machine with a stainless steel and rust-resistant body is more expensive than those made with iron or other metals.

- The size and dimensions of the filling machine also affect its price, with larger models being more expensive compared to smaller ones.

- Another factor that can directly affect the price of the filling machine is the number of nozzles. The more nozzles there are, the higher the price of the machine.

- The mechanism of the machine’s operation is also directly related to its price, such that fully automatic models are more expensive than semi-automatic or manual ones.

In general, it is not possible to set a specific price for this machine, and each company can have a different price range for it based on their order and expectations from the machine. If you aim to purchase a suitable machine at an ideal price, we recommend choosing a semi-automatic model or a fully automatic model with a smaller number of nozzles.

Acquiring a carbonated liquid filling machine

When acquiring this machine, we recommend paying close attention to the physical specifications, brand, and place of purchase. Since filling machines are costly and neglecting their functionality can lead to significant losses for organizations, it’s crucial to purchase these machines from reputable stores. Before buying, be sure to examine various parts of the machine, such as the type of nozzles, the connection of the nozzle to the bottle opening, the used jacks, the body material, and other components.

Technical specifications of carbonated liquid filling machines.

The technical specifications of these machines include having a stainless steel tank, which can come in different volumes, with the appropriate volume chosen based on the specific needs. These machines have a steel cover that prevents the body from rusting. Another part of the machine is the printer, which prints the required information, such as the production and expiration dates, on the bottle or can.

Other components, such as conveyors, the container and bottle washing section, are also found in carbonated beverage filling machines. Additionally, the machines are equipped with various electronic systems and controllers, where operational instructions can be entered and viewed. Furthermore, the machines have a shrink-wrapping section that places the final cans or bottles into boxes in packs.

The operation of a soda filling machine

As mentioned in the production line section, the operation of soda filling machines works as follows: the container is placed on a conveyor belt. This container can be made of PET or metal/plastic cans. The conveyor belt systematically directs the containers towards the nozzle, and along the way, they may undergo washing. Finally, the nozzle connects to the bottle’s opening, followed by the filling of the bottle with soda.

After the bottle is filled with the desired volume or weight, the nozzle is detached, and the bottle’s opening is sealed. Finally, we have the labeling and shrink-wrapping sections, where the prepared and filled soda bottles are placed into the desired boxes and exit the machine.

Summary

The filling machine is specifically used for filling various liquids, including thick and thin liquids, as well as gases and solids. One of the main challenges for manufacturers is filling carbonated liquids accurately into the desired container. These liquids, in turn, do not have a high viscosity, but the machines used to fill them are of the type designed for thick liquids.

Carbonated liquids can be filled into PET bottles or metal and plastic cans, with different machines available depending on the type of bottle. When purchasing this machine, factors such as whether it is automatic or semi-automatic, the material of the body, the type of piston, the nozzle connection to the bottle neck, and so on should be considered to ensure a suitable purchase.

Frequently Asked Questions

What substances are considered carbonated liquids?

These liquids include various carbonated beverages such as soda, sparkling water, kefir, and others, which are generally low in viscosity.

Which machine can be used for filling carbonated liquids?

The carbonated liquid filling machine operates similarly to the filling machine for thick liquids, and typically, machines with a piston cylinder or pump system are used for them.

What factors should be considered when purchasing a carbonated liquid filling machine?

When purchasing this machine, attention should be given to the material of the body (which should be stainless steel and rust-resistant), dimensions, number of nozzles, the brand, whether it is automatic or semi-automatic, and other factors.