Today, the demand for hygiene products such as shampoo has significantly increased due to the need for cleanliness and preventing the spread of the COVID-19 virus. According to a global survey, the shampoo market is expected to reach $1.48 billion by 2024. Therefore, if manufacturing and selling shampoo is your goal, you will have a significant advantage in the market. You just need to find the right formula and acquire the necessary equipment.

Given the increasing trend of using cosmetic and hygiene products, one of the most successful production lines is the shampoo production and packaging line. Establishing this production line will create an opportunity to enter a profitable and income-generating market. This hygiene product has a high variety and will allow for flexible production. In the following, we will provide a more detailed introduction to this process and other factors that affect the income of a shampoo production line.

If you have such an intention, stay with us in this article as we explore what a shampoo production line is and what equipment it consists of.

What is a shampoo production line?

It is interesting to know that before the invention of shampoo in its modern form, people used plant-based materials like henna, soapwort, and gum tragacanth, as well as mineral substances like silica clay, to wash their hair. However, with the increasing demand and the availability of new technologies, shampoo production became a profitable business, and many companies and brands started their activities in this field.

According to the statistics we previously provided, today anyone can start producing this profitable product by purchasing a shampoo production line and creating a unique formula. It is worth noting that the final quality of cosmetic and hygiene products, including shampoo, depends not only on the quality of raw materials but also on the quality of manufacturing and packaging equipment. Therefore, the necessity and application of a shampoo production line in factories cannot be denied.

Types of shampoo based on packaging

In general, shampoos are categorized based on various factors. One of these categories is based on their therapeutic use. In this classification, shampoos are divided into the following types:

- Repairing

- Moisturizing

- Antifungal and anti-dandruff

- and …

They are divided.

They are also categorized based on hair type into the following categories:

- Suitable for dry hair

- Oily hair

- Mixed and normal hair

They are.

In addition, some are fortifying and contain extracts such as argan, almond oil, vitamins, etc. Finally, they may be categorized based on their fragrance, containing aromatic elements such as lavender, lemon, flowers, and so on. In general, it can be said that the main difference lies in the product’s formulation, and in the production line, they are separated based on the type of formulation from other products.

Stages of shampoo production

Shampoo production is a process in which chemicals are combined with therapeutic ingredients to create the final product. In general, this process includes the following stages:

- Research and development

- Preparation of raw materials based on the type of shampoo

- Mixing and formulation of ingredients

- Testing and quality control

- Mass production of shampoo solution

- Final processes and removal of impurities

- Filling and packaging

- Labeling and date coding

- Final quality control

- Storage and distribution

Each of these stages involves various processes and requires specific machines and equipment in the production line. With the help of modern technologies and high-quality production line equipment at each stage, the final product will also have higher quality.

List of equipment required for shampoo production line

But what are the equipment for a shampoo production line? A person who wants to start a shampoo manufacturing business should think about purchasing which machines? Below is a list of the necessary equipment for setting up a shampoo production line, along with explanations for each.

- Raw Material Loading Tank

- Transfer Pump

- Shampoo mixer

- Calming tank

- Liquid Filling Machine

- Labeling machine

- Capper machine

- Packaging machine

- Cartoning Machine

- Laboratory equipment for quality testing

It is worth mentioning that by purchasing the mentioned equipment, you can produce and package not only shampoo but also detergent production lines, dishwashing liquid production lines, cosmetics production lines, and any product that is considered a thick liquid and can be packaged in the mentioned containers.

✅ Raw material loading tank

What is the purpose of the tank in the shampoo production line? A storage tank or raw material loading tank is a container designed and built for holding liquids. These tanks are available in metal and plastic types, but for shampoo production, it is better to use stainless steel to ensure resistance to corrosion. Another very important point regarding the raw material loading tank is its ability to be cleaned and sanitized, ensuring that it can withstand the cleaning and sanitizing materials used.

✅ Transfer pump

A transfer pump is an electro pump used for transferring chemicals, mixtures, or heavy liquids such as shampoo and oil. These pumps are typically made of steel or polymer, offering high resistance to corrosion and wear. The most important factor when purchasing a transfer pump is to pay attention to the type of impeller blade or the material of the impeller, as it is one of the most crucial parts of the pump. Its rotary motion increases the fluid speed.

✅ Mixer

The shampoo mixer should be designed in a specialized and proper manner. Important features that the mixer should have include multi-layer construction and heating capabilities. Additionally, mixers used for producing specialized or pharmaceutical shampoos must have circulation and homogenization capabilities. The Radan Machine vacuum homogenizer mixer is the best option for a shampoo production line.

✅ Calming tank

One of the advantages of the shampoo production line is having various pieces of equipment that are essential for shampoo manufacturing. One such piece of equipment is the calming tank, where the produced shampoo rests for a period of time, allowing the bubbles to fully dissipate, preventing any issues during the packaging process.

✅ Filling Machine

The liquid filling machine is used for filling shampoo into bottles; however, what are the types of filling machines that can be used in a shampoo production line? Two types of filling machines, piston cylinder fillers and pump fillers, can be used in this production line. Pump fillers are more suitable for semi-viscous liquids and foaming liquids, and are produced in three types: gear, centrifugal, and screw. The most suitable filling machine for a shampoo production line is the Radan automatic gear pump liquid filling machine, which is also applicable for other liquids such as hand wash, dishwashing liquid, oils, syrups, and more.

For more information, pricing, and to purchase the thick liquid filling machine, please click on this link.

✅ Labeling machine

The labeling machine, as the name suggests, is used for attaching labels containing product details onto its packaging. These labels provide important information such as price, production date, expiration date, usage instructions, etc., to the consumers. The best labeling machine for a shampoo production line is the Radan self-adhesive labeler, which is available in both flat and round types.

Capping machine

The capping machine is responsible for placing the cap onto the bottle’s neck and securing it. Depending on the type of cap, its shape, and the shape of the shampoo bottle, you should select a capping machine with the appropriate mechanism. This device, which is available in trigger, eight-head, and two-head models on the Radan Machine website, is an essential part of the production line as it significantly increases the production speed.

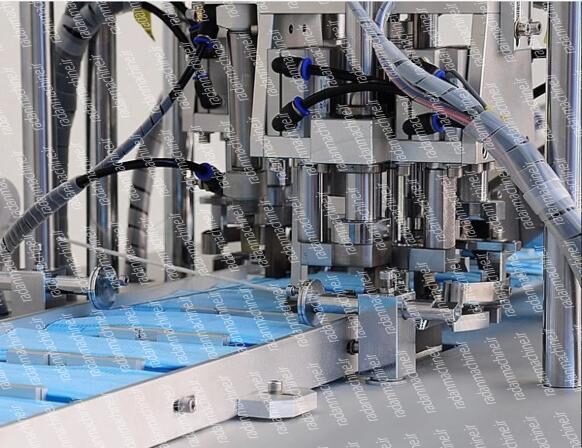

✅ Packaging machine

What is a packaging machine in a shampoo production line? This machine is one of the essential components of the shampoo production line, designed to group multiple products into a single package, preventing damage to the primary packaging, ensuring easy product transportation, and keeping the product intact. The shrink wrap machine is one of the types of packaging machines that you can purchase from Radan.

✅ Cartoning Machine

The process of placing a product into a box or carton is called cartoning. According to this definition, the cartoning machine in the shampoo production line is used to place the packaged shampoos into cartons without manual intervention, ensuring product safety, quality, and hygiene.

In this section of the shampoo production line, the carton sealing machine plays a significant role. This machine, which is capable of sealing both light and heavy cartons, applies adhesive to the cartons in the final stage of shampoo packaging, making them easier to transport. You can purchase this machine through the Radan Machine website.

✅ Laboratory equipment for quality testing

For testing shampoo and other cosmetic products, tests such as stability tests (evaluating the product under different temperatures and environmental conditions), microbiological tests (assessing the product’s ability to prevent microbial growth during use), and packaging stability tests (evaluating the effectiveness of the product’s container or bottle) are typically conducted. The following equipment is required to perform these tests:

- Digital scale

- Incubator (temperature range 10-50°C)

- Viscometer

- Microbial test kit

The importance of using the best equipment in shampoo production line

In the first step, the quality of the equipment provides a vision of the final product. Using modern and up-to-date machines will lead to the production of high-quality products, which will result in customer satisfaction. This level of satisfaction increases the market demand for the product, thereby boosting the final profit.

On the other hand, high-quality equipment has a high production speed and is capable of delivering products quickly and without interruption within a specified time frame. This, in turn, impacts profitability. Additionally, these machines have minimal error rates, impurity production, and waste, leading to significant savings in capital. Ultimately, the higher the quality of the equipment, the less frequent the need for repairs and replacements. The reduced need for repairs and part replacements results in substantial capital savings.

It is worth mentioning that modern machines, which are in line with the latest technology, offer greater versatility, thus enabling flexible production. In this case, there is no need to purchase multiple machines. Instead, with the help of a single machine, several tasks can be performed. This reduces the need to acquire multiple machines and even minimizes the requirement for hiring additional staff.

Therefore, it is recommended that founders of shampoo production lines allocate a suitable initial investment for purchasing the necessary equipment, as this will gradually lead to the highest level of profitability over time.

What factors determine the price of a shampoo production line?

The final price of purchasing and setting up a production line depends on several factors. Some production lines are valued higher than others. The influencing factors on the final value of a production line are:

- Production Capacity

- Technology and quality of the machines and equipment in the production line

- The number of human resources

- The quantity and quality of raw materials

- Software technology and control system

- Industry standards and regulations

- Technical support and after-sales services

These factors are considered in the final valuation of a production line, and a production line that can meet all of these parameters will be considered a successful one.

The process of purchasing machines and equipment for a shampoo production line

Radan Machine Company provides all the equipment for the shampoo production line. This company offers all equipment from A to Z for its customers. The equipment is highly diverse, providing a wide range of choices for customers. For example, when purchasing a shampoo filling machine, customers can choose from various filling machines for thick, thin, and mixed liquids. This diversity feature is maintained for all products.

On the other hand, all of these products come with a warranty and authenticity guarantee. This warranty, along with the assurance of after-sales service, is aimed at gaining the buyer’s satisfaction and trust. By purchasing all the equipment for the production line and the complete liquid packaging line from Radan Machine in a single purchase, there is no need to buy from multiple companies, and the production line will be ready for operation in the shortest possible time.

Frequently Asked Questions

What material should the transfer pump in a shampoo production line be made of?

The transfer pump should be made of stainless steel or polymer that is fully resistant to various chemicals and acids.

Is having a sealing system essential in a shampoo production line?

No, because this system is responsible for sealing the shampoo cap, but most shampoos are sold in the market without a seal.

What machine is recommended for filling shampoo?

Considering the viscosity of this product, suitable options include the semi-automatic single nozzle piston cylinder filling machine RPF20, the semi-automatic double nozzle piston cylinder filling machine RPF20, and the automatic gear pump liquid filling machine RPF40.

What will be the final price of a shampoo production line?

This depends on several factors and will range from 1 to 2 billion and above. This is because the variety of initial equipment for the production line is high, and there is a wide range of prices. It is recommended to visit the product list on Radan Machine’s website for accurate pricing information.

What is the best mixer for stirring shampoo raw materials?

Horizontal mixers, viscosity mixers, homogenizers, and others can perform well in stirring the chemical compounds of shampoo.

Final Words

In this article, we reviewed what a shampoo production line is and what equipment it consists of. Shampoo production and sales is a lengthy process that involves various stages, including formulation, raw material storage, mixing, packaging, and testing. We hope this guide has helped you in selecting the necessary equipment for shampoo production. Finally, it is worth knowing that Radan Machine is one of the top companies designing and manufacturing specialized machinery for the food, pharmaceutical, cosmetic, hygiene, and chemical industries. If you are looking to purchase equipment for a shampoo production line, you can acquire all the necessary machines from Radan Machine.